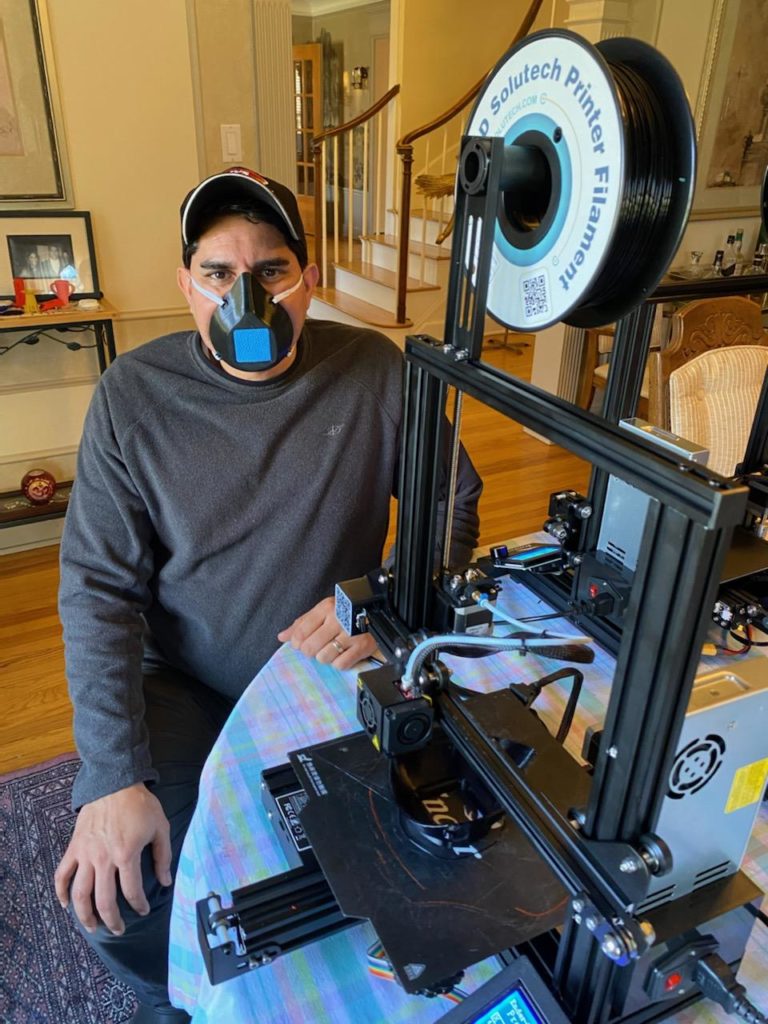

Dr. Bobby Mukkamala wearing a finished mask from his home 3D production (photo from the Mukkamala family)

By Jan Worth-Nelson

From his own dining room table and living room, local physician and downtown community advocate Dr. Bobby Mukkamala and his family are cranking out dozens of desperately needed surgical masks.

Mukkamala and his son Nikhil, an engineering student home on “coronavirus leave” from the University of Michigan, have produced about 200 masks so far on a set of 3D printers in their rapidly-crafted home “maker space.”

It takes about three hours and costs less than a dollar to make each mask, which Mukkamala, president-elect of the Michigan Medical Society, is donating to Hurley Medical Center and additionally shipping to some of his colleagues in hot spots around the country.

He is mailing out several boxes a day — about a dozen so far, he said. And he dropped off a supply to Hurley yesterday to see if his masks can fill the bill for the much-needed N-95 masks used daily.

A number of serendipities have come together to propel the home-based production and make it possible. First, he had the printers available in his home office–in total, about 23 of them –including a donation waiting to be delivered to the Flint Community Schools and delayed by the school closures.

Nikhil Mukkamala fits a mask on a mannequin (photo by Bobby Mukkamala)

Second, Nikhil is home from Ann Arbor because of the coronavirus from the University of Michigan. Third, Mukkamala, an otolaryngologist and indefatigable downtown activist, said he is down to about a quarter of his regular practice schedule.

And fourth, Mukkamala, who’s also on the national board of the American Medical Association, knew that something needed to be done.

Mukkamala and his son already had 3D printers of their own, but six months ago, he bought 20 more to donate to each of the Flint Community Schools as part of the CRIM Foundation’s community schools program. He hadn’t yet delivered them, so was able to open them up and set them up for service.

From the inventory of printers Mukkamala fortuitously had on hand, he has given four to Kettering University students and two to friends, assembling a team of eight using one or more printers each for mask production.

A “Montana” model

The Mukkamalas are building their masks on a model called “The Montana Mask,” based on a design from the University of Montana that has been highly rated for providing reliable protection and efficiency. He says with appropriate filtering material, the Montana Mask can qualify as an N-99, meaning it can filter out 99 percent of the virus even better than the standard N-95s.

Mukkamala says he’s giving first priority to medical personnel who need them most, and after that, if the supply is adequate, would possibly offer them to the general public.

On Sunday Mukkamala and his son had four printers going making masks and another machine making a component part, a piece to hold the mask material in place.

The masks have just three material elements: the plastic filament the machines use to weave the mask itself, the elastic bands that go around the head, and the crucial squares of filtering material.

The latter is crafted from surgical wrap material used in hospitals to keep surgical tools sterile–Mukkumala said he was able to get plenty from Hurley for that part of the design.

Add a glue gun and staples and a bit of dexterity — Mukkamala said even an elementary school student could to it — and the mask is ready.

The plastic filament comes on spools and Mukkumala said he had a basement full of them and has ordered more.

The hardest part to find so far has been the elastic band — in high demand not just for surgical masks but for the cloth masks now being generally recommended even for non-medical personnel in daily life. He obtained some from Walmart, which is now sold out. In the meantime, he got some elastic from Chrysa Cronley, a downtown Flint dressmaker who is making cloth masks herself for the general public.

About wearing masks: There is “no down side of being prudent”

While the Mukkamalas are giving first priority for their masks to the hospitals, Dr. Bobby says he thinks the recommendation for the public to wear cloth masks is a good one.

“If you’re going to be within six feet of anybody, you have nothing to lose,” he said. “Your first goal should be staying away from as many people as possible…but as for the masks, I don’t see the down side of being prudent.”

The 3D printers cost about $250 each, Mukkamala said, but he managed to get them from a sympathetic manufacturer at a discount of about $215.

For Nikhil, who’s aiming for a career in bioengineering, the coronavirus situation is providing a “living lab,” Mukkamala said.

Not enough testing capacity

As for the status of the coronavirus in general, Mukkamala is watchful and says the future is more full of questions than answers.

“It’s a matter of bracing for a worse day tomorrow than what we’re going through today,” he said. “There are all these unknowns.”

As for local readiness, Mukkumala said “We’re not at full capacity,” yet.

Certainly there is not enough testing capacity, he noted, saying that even physicians are having trouble getting test kits. A local physician’s father died of the virus in the ICU recently, he said, and it’s quite possible the physician himself passed on the disease–but the doctor couldn’t get tested himself, because he isn’t displaying symptoms. Because he doesn’t know for sure, he has had no choice but to isolate himself.

Hospitals have limited capacities to test their own patients, he said, but there’s not enough for anybody else.

“If you’re not sick, or just a little bit sick, we don’t have enough tests to test you, so you should just isolate yourself,” he said.

Reflecting on all the adjustments and challenges the virus is presenting to the community, Mukkamala said, “Eventually, we will get through this…I hope this will be the last time in my lifetime, but probably not.

“Hopefully, we will learn lessons from it so that we won’t make the same mistakes again,” he said.

Mukkamala said he looks forward to when he can get the twenty 3D printers into the Flint Community Schools, where he hopes students can get ahead of the curve in learning a skill that may be of great application to the world and seeing what doors that might open.

EVM Editor Jan Worth-Nelson can be reached at janworth1118@gmail.com.

You must be logged in to post a comment.